A-A-52446

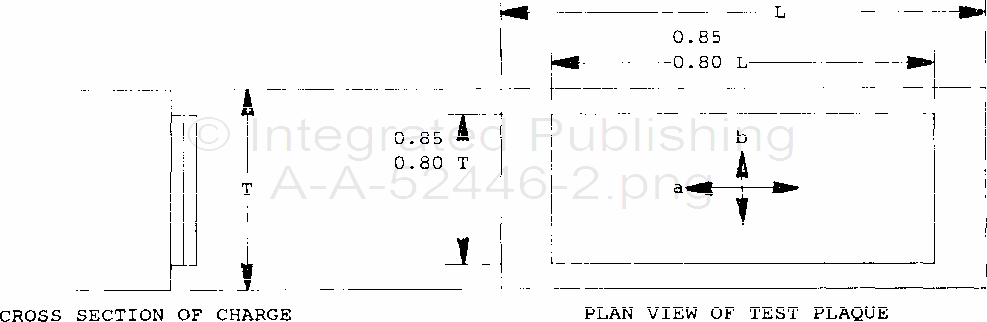

c. Properties of SMC material. the SMC material shall be molded into test plaques to verify conformance to the physical and mechanical properties specified herein. The test plaques shall be 2.5 ± 0.1 mm thick and shall be molded using the same cure cycle, mold temperature, and mold pressure as is used to mold the production items (parts). The charge pattern used to mold the test plaques shall conform to the conditions specified in figure 1, unless the combination of SMC sheet weight and plaque mold dimensions make this possible.

Legend:

L = Longitudinal dimension of mold.

T = Transverse dimension of mold.

a = Indicated is the longitudinal direction of the SMC in charge no. 1 (sometimes referred to as the machine direction of the SMC).

b = Indicated is the longitudinal direction of the SMC in charge no. 2.

FIGURE 1. Charge pattern conditions.

1. Physical and mechanical properties. The physical and mechanical properties of the SMC material shall be as specified in table I.

d. SMC molded parts. The properties and performance requirements of SMC molded parts shall be as follows:

1. Properties of SMC molded parts. The physical and mechanical properties of SMC molded parts and verification of same shall be as specified in table I (for parts thicker than 2.5 mm use 0.5 mm offset for second modulus). The part of specimens made from the part, as appropriate, shall be used for this purpose. For glass fiber content, at least five specimens shall be taken at random from the part.

2. Performance/environmental requirements.

(a) Dimensional stability. The SMC molded parts shall maintain their dimensions and tolerances, as specified in the AED, before and after exposure to 150° for 90 minutes. Also, the parts shall not blister or show any other deleterious effect after exposure.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business