MIL-PRF-5425E

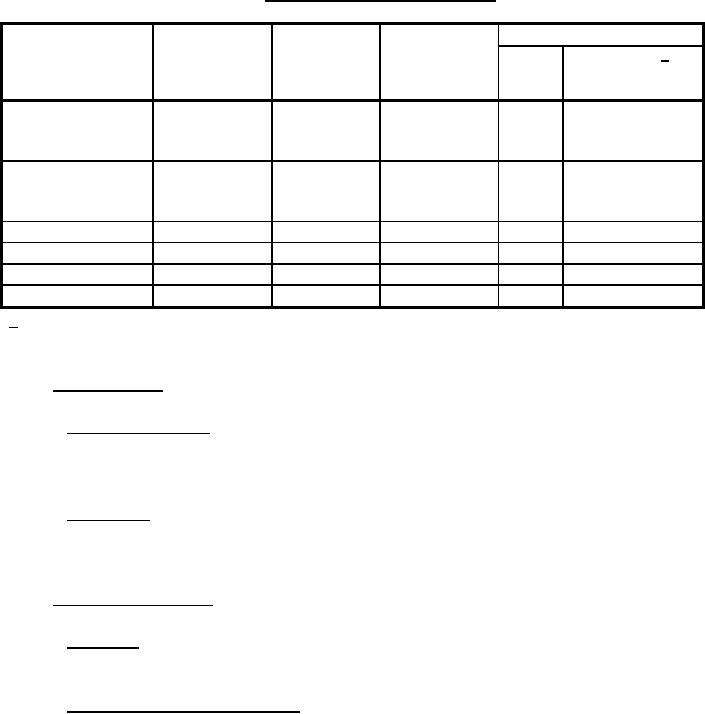

TABLE VI. Physical and mechanical inspection.

NUMBER

RESULTS RECORDED AS

OF DETER-

PASS

AVERAGE (1/)

REQUIREMENT

TEST

MINATIONS

OR

NUMERICALLY

CHARACTERISTIC

PARAGRAPH

PARAGRAPH

PER SAMPLE

FAIL

TO THE NEAREST:

-

0.1 °C

Flexural

Table II

4.5.5

2

deformation

temperature

-

Luminous

Table II

4.5.9

2

0.1 percent

transmittance, as

received

-

Haze, as received

Table II

4.5.9

2

0.1 percent

-

Optical defects

3.6.1

4.5.12.1

2

X

-

Angular deviation

3.6.2

4.5.12.2

2

1 minute

-

Thermal stability

Table II

4.5.13

1

X

1/ All values shall be recorded.

4.4 Test conditions.

4.4.1 Standard conditions. Unless otherwise specified in the applicable test method, all tests

and inspections shall be conducted at a temperature of 77 ±2 °F (25 ±1 °C) and a relative

humidity of 50 ±5 percent.

4.4.2 Test results. Unless otherwise specified in the applicable test method, all test results

shall be recorded as the average of the number of specimens being tested as well as each

individual value.

4.5 Methods of inspection.

4.5.1 Thickness. Thickness measurements shall be made with any device having an accuracy

of 0.001 inch (0.025 mm) and shall meet the requirement of 3.2.3.

4.5.2 Coefficient of thermal expansion. Two test specimens shall be tested in accordance

with ASTM-D696. If the results obtained on the two specimens are within 10 percent, the

average of the two values shall be recorded. If not, the test shall be repeated. Results shall meet

the requirement in table II.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business