MIL-PRF-87260B(USAF)

ΔP

ΔT

Vc

SPARK

Va

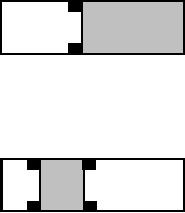

a. Typical set-up for single void ignitions.

ΔP

ΔT

Va

Vv

Vc

SPARK

b. Typical set-up for arrestor thickness tests.

FIGURE 3. Flame arrestor apparatus

4.5.18.2.1 Single void ignitions.

Single void ignitions shall be conducted at 3 psig (17.7 pounds per square inch absolute (psia))

initial pressure with the following minimum number of percent combustion volumes (percent VV)

of:

a.

Grade I: 10, 15, 20, and 30 volume percent

b.

Grade II: 20, 30, 35, and 40 volume percent

A minimum of two tests shall be conducted for a given condition and all data such as bomb

sample and system pressure rise, test temperature, extent and location of arrestor damage, and

any other related information shall be submitted to the coordinating activity. A plot of pressure

rise (psid) versus (percent) combustion volume shall be submitted for each initial pressure

condition. Repeat test may be conducted on the material provided the damaged (burned)

arrestor is replaced after each test. All tests shall be conducted at standard laboratory

conditions.

4.5.18.2.2 For Grade II (fine pore material only).

Determine the amount of arrestor (thickness) required to prevent flame propagation from Vc to

VV when the combustion volume (Vc) is 9.1 and 16.7 volume percent and the initial pressures

are 0 and 3 psig. Testing shall be conducted at 1 inch (thickness) intervals until the minimum

arrestor thickness (Tm) is determined. Then a minimum of two tests shall be conducted to verify

the minimum thickness. All data including system and bomb pressure rise, test temperatures,

extent and location of arrestor damage, and any other related information shall be reported.

The ratio of arrestor volume to combustion volume (Va/Vc) shall be calculated for each minimum

arrestor thickness (Tm).

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business