MIL-DTL-24191D(SH)

4.

VERIFICATION

4.1 Inspection conditions. Unless otherwise specified, all inspections

shall be performed in accordance with the test conditions specified in 4.5 and

4.6.

4.2 Classification of inspections.

The inspection requirements specified

herein are classified as follows:

(a)

First article inspection (see 4.3).

(b)

Conformance inspection (see 4.5).

4.3 First article inspection. The sample for first article inspection shall

be subjected to the tests of table V.

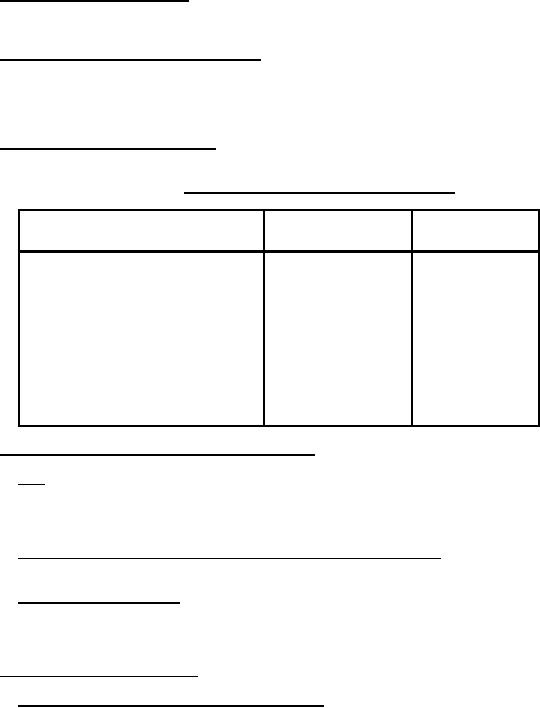

TABLE V.

First article inspection tests.

Requirement

Test

Tests

paragraph

paragraph

Dimensional examination

3.2, 3.3, 3.5

4.5.1

Formability

3.4

4.6.9

Optical uniformity

3.5

4.5.1

Specific gravity

3.6

4.6.2

Deflection temperature

3.7

4.6.3

under load

Water absorption

3.8

4.6.4

Flammability

3.9

4.6.5

Flexural strength

3.10

4.6.6

Impact strength

3.11

4.6.7

Optical properties

3.12

4.6.8

4.4

Sampling for conformance inspection.

4.4.1 Lot. All material of the same type, grade, and thickness manufactured

under essentially the same conditions from the same batch of material and offered

for delivery at the same time shall be considered a lot for purposes of

inspection.

4.4.2 Sampling for visual and dimensional examination. A random sample of

sheets shall be selected from each lot offered for examination (see 6.2 and 6.7).

4.4.3 Sampling for tests. A random sample of sheets shall be selected from

each lot, except that only one sheet shall be selected from lots of 40 or under.

The random sample shall be subjected to the tests specified in 4.6 (see 6.2 and

6.7).

4.5

Conformance inspection.

4.5.1 Visual and dimensional examination. Each sample sheet selected in

accordance with 4.4.2 shall be subjected to visual and dimensional examination to

determine compliance with 3.2, 3.3 and 3.5. If any sheet in the sample contains

one or more defects, as defined in 3.5.1 and 3.5.2, it shall be rejected, and if

the number of rejected sheets in the sample exceeds the acceptance number for that

sample, this shall be cause for rejection of the lot represented by the sample.

The thickness shall be determined by the use of a suitable instrument, accurate to

0.001 inch. Five measurements shall be made at random points on the sheet.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business