MIL-DTL-24191D(SH)

4.5.2 Conformance tests. Conformance tests shall be conducted on the sample

sheets selected in accordance with 4.4.3 and shall consist of the tests specified

in table VI. Results shall be averaged for each sample sheet to determine confor-

mance with this specification. If the average for any sheet fails to conform with

any requirement, this shall be cause for rejection of the lot. Color (chromati-

city) and luminous transmittance do not apply to types RTPS-2, BTPS-2, and CLEAR-2.

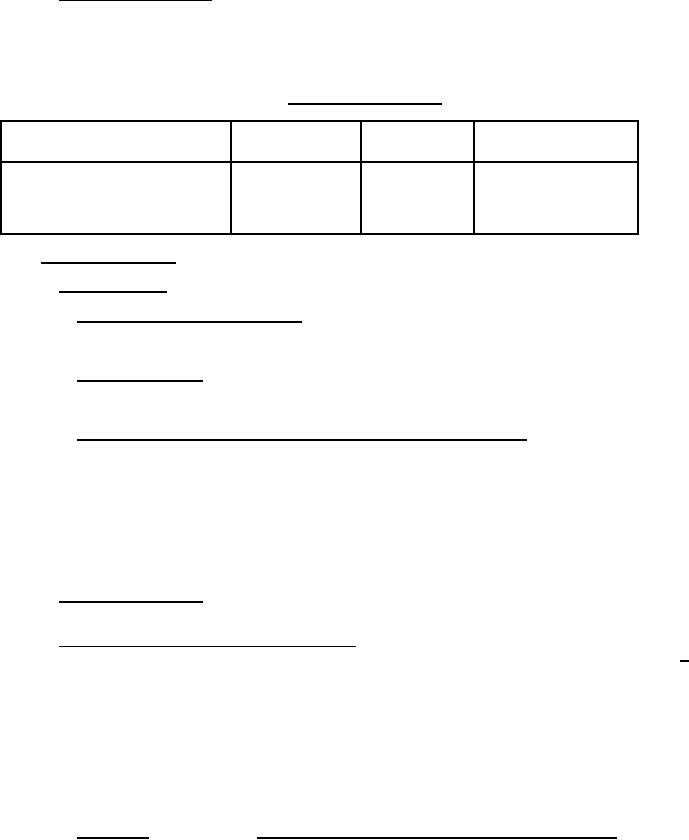

TABLE VI.

Conformance tests.

Requirement

Test

Number of

Test

paragraph

paragraph

determinations

Specific gravity

3.6

4.6.2

1

Deflection temperature

3.7

4.6.3

3

under load

Optical properties

3.12

4.6.8

1

4.6

Test procedures.

Test samples.

4.6.1

4.6.1.1 Condition of test samples. Samples shall be tested in the "as

received" condition; that is, no special conditioning shall be required unless

otherwise specified in the test procedure.

4.6.1.2 Test thickness. Tests shall be made on sample sheets of nominal

thickness shown in table I. If sample sheets are tested other than at the nominal

thickness, the test results shall be adjusted to the nominal thickness.

4.6.1.3 Test samples for types RTPS-2, BTPS-2, and CLEAR-2. Test samples

for RTPS-2, BTPS-2, and CLEAR-2 shall be prepared by either of the following

methods:

(a)

The patterned surface shall be ground down to the nearest nominal

thickness shown in table I and polished to a smooth surface.

(b)

The test specimen shall be cast with a smooth surface finish on

both sides to the nearest nominal thickness shown in table I from

the same batch material as that used for the production sheets

under test.

4.6.2 Specific gravity. The specific gravity of the material shall be

determined in accordance with ASTM D 792.

4.6.3 Deflection temperature under load. Conditioned test specimens shall

be tested. The length of the specimen shall be 5 inches, the depth shall be 0.5 +

0.005 inch, and the width shall be the thickness of the original sheet. Thin

sheet materials, less than 0.125 inch (namely 0.060, 0.080 and 0.100 inch) shall

be arranged to form a composite specimen of convenient thickness. The apparatus

shall be similar to ASTM D 648. The conditioned specimen shall be supported as a

simple beam on steel supports 4 inches apart with the load applied vertically on

the top of the specimen midway between the supports. The 1/2-inch dimension or

depth of the beam shall be vertical. The load applied shall be governed by the

width of the specimen and shall in each case induce in the specimen a maximum

outer fiber stress of 264 lb/in2. The loads applied for typical specimens are as

follows:

Specimen

Load applied midway between the supports

1/4 by 1/2 by 5 inches

2.75 pounds

1/8 by 1/2 by 5 inches

1.38 pounds

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business