MIL-PRF-23653D

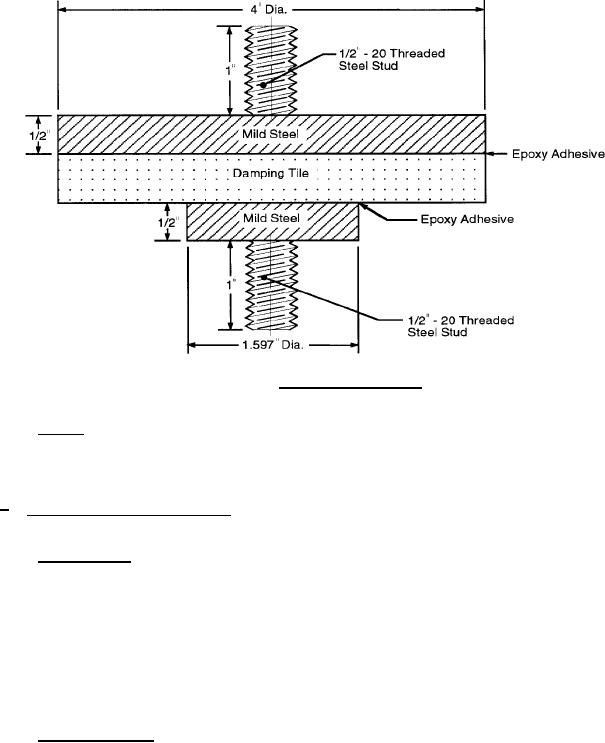

FIGURE 1. Adhesion test specimen.

4.4.5.2 Testing. The testing shall be conducted at 80±9 °F (27±5 °C). The test specimen shall be placed in a

tension testing machine and the force required to separate the small disc from the specimen determined. The rate of

separation of the tension testing machine fixtures shall not exceed 1 inch per minute. The test shall be repeated on

each of the remaining specimens. The results from the three specimens shall be averaged.

4.4.6 Vibration damping characteristics. Vibration damping characteristics shall be determined as specified in

4.4.6.1 Test specimens. The test specimens for determining vibration damping characteristics shall be as

follows:

a.

One flat steel bar,

by 3 by 40 inches.

b.

Three flat steel bars, each by 3 by 40 inches, with strips of damping tile completely covering one 3- by

40-inch face on each bar (the bar from 4.4.6.1.a. may be used after measurement of bare bar damping

characteristics). Starting at one end, three strips of damping tile, nominally 3 by 12 inches, shall be bonded to

each bar followed by a final strip, nominally 3 by 4 inches, applied to the opposite end. The 3-inch edge of

each strip shall be square and butted up against the edges of adjacent strips. The damping tile strips shall be

bonded to the steel bars in accordance with the procedure detailed in 4.4.6.2.

4.4.6.2 Bonding procedure. The damping tile strips (see 4.4.6.1.b) shall be cleaned with PF Degreaser or equal

(see 4.4.5.1.2) and allowed to dry thoroughly in ambient conditions. The face of each steel bar to which damping

tile strips will be applied shall be cleaned with PF Degreaser or equal, then abrasive blasted to SSPC-SP 10 with a 2-

to 4-mil profile and cleaned again with PF Degreaser or equal after blasting. The final degreaser cleaning shall

occur immediately prior to bar assembly. The degreaser shall be allowed to dry completely after each use. A coat

of paint, with a maximum dry film thickness of 3 mils, may be applied to the unbonded surfaces of the steel bars to

protect against corrosion. MIL-A-24456 adhesive shall be mixed in accordance with the manufacturer's instructions

and shall be applied with a notched trowel. The notches in the trowel shall be equilateral triangles 3/16±1/32 inch deep.

The triangles shall intersect each other. The damping tile strips shall be pressed firmly down onto the prepared

surface of the three bars. Adhesive shall not be applied in the seams between the tiles. Excess adhesive shall be

removed from the sides of the tile strips and steel bars. The assembled test specimens shall be allowed to set at

80±9 °F (27±5 °C) for a minimum of 96 hours prior to temperature conditioning for the vibration damping tests.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business