MIL-DTL-62474F

b. Type I and II (except autoclave).

1. Press platen temperature increased to 330 +10°F (166 +6°C).

2. Dwell in accordance with schedule of Table II (Class A and B) with platens at

330 +10°F (166 +6°C). Use Table IIa for dwell time based upon areal

densities (AD) of the ply layup for class C and D laminates.

3. Press platen temperature reduced to a maximum of 180°F (82°C) before

laminate removal.

c. Type II (autoclave)

1. Autoclave temperature increased to 330 +10°F (166 +6°C).

2. Dwell in accordance with Table II (Class A and B) with autoclave at

330 +10°F (166 +6°C). Use Table IIa for dwell time based upon areal

densities (AD) of the ply layup for class C and D laminates.

3. Autoclave temperature reduced to a maximum of 180°F (82°C) before

laminate removal.

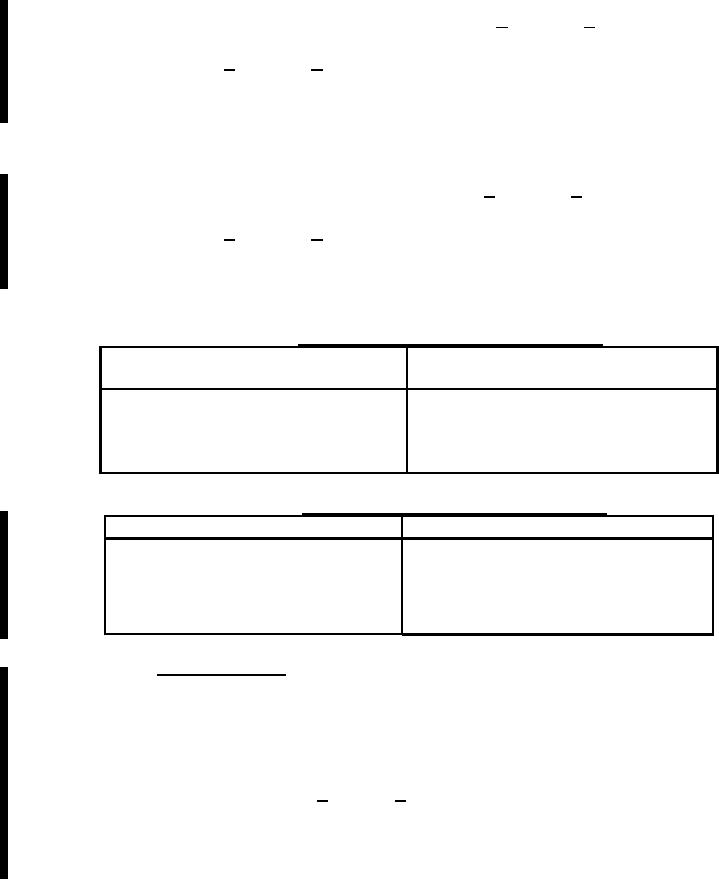

TABLE II. Laminating dwell times for Class A and B.

Laminate plies

Dwell time

(number)

(minutes)

1-10

30

11-20

45

21-30

75

31-40

75

TABLE IIa. Laminating dwell times for Class C and D.

Laminate AD (psf)

Dwell time (minutes)

< 1.5

30

1.5 3.0

45

3.0 4.5

75

> 4.5

75

3.3.3 Finished laminate. The finished laminates shall consist of the specified number of

plies (A and B) or areal density (C and D) sandwiched between single peel-plies which can be

incorporated in the lamination process. Peel-plies coated with a release agent shall not transfer

to the laminate surfaces. All cutting and machining of laminate panels shall be done with the

peel-plies intact. Wet cutting and machining procedures shall be followed by a drying process.

The drying process shall consist of drying the panel in a forced draft or convection type oven in a

stream of ambient air heated to 200 +10°F (93 +6°C) for a period of not less than four hours.

NOTE: This drying requirement shall be waived if an abrasive water-jet cutter is used. Any

resulting moisture film remaining on cut surface shall be removed by local heat application

(heater/blower) or by using clean, dry toweling. The finished laminate shall have an epoxy resin

sealed surface on all cut, trimmed or drilled hole edges which is applied after any required drying

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business