MIL-DTL-62474F

process. The epoxy resin used shall have a service temperature of not less than 250°F (121°C)

and meet the requirement of 3.4.2. Application of the resin shall not interfere with the peel-ply

removal (see 4.3.3 and 4.3.4.1).

3.4 Performance.

3.4.1 Peel-ply removal. The peel-plies are intended to keep panel surfaces clean and

shall be easily removable by hand, without requiring heat or solvents. Laborious or difficult

removal shall be unacceptable (see 4.3.4).

3.4.2 Temperature resistance. The plastic laminates shall not show evidence of

delamination following a two cycle exposure to a temperature range of -65°F to 250°F (-54°C to

121°C) (See 4.3.4 and 4.3.4.3).

3.4.3 Ballistic resistance. For class A and B laminates, the V50 protection ballistic limit

as defined in MIL-STD-662 shall not be less than that indicated in Table III for the number of

plies indicated when tested as specified in 4.3.5. For class C and D laminates, the V50 protection

ballistic limit as defined in MIL-STD-662, the velocity at which the probability of penetration of

an armor material is 50 percent shall not be less than 2600 ft/s (793 m/s) for a laminate of

nominal areal density of 5.0 +/- 0.1 psf (24.4 +/- 0.5 Kg/m2).

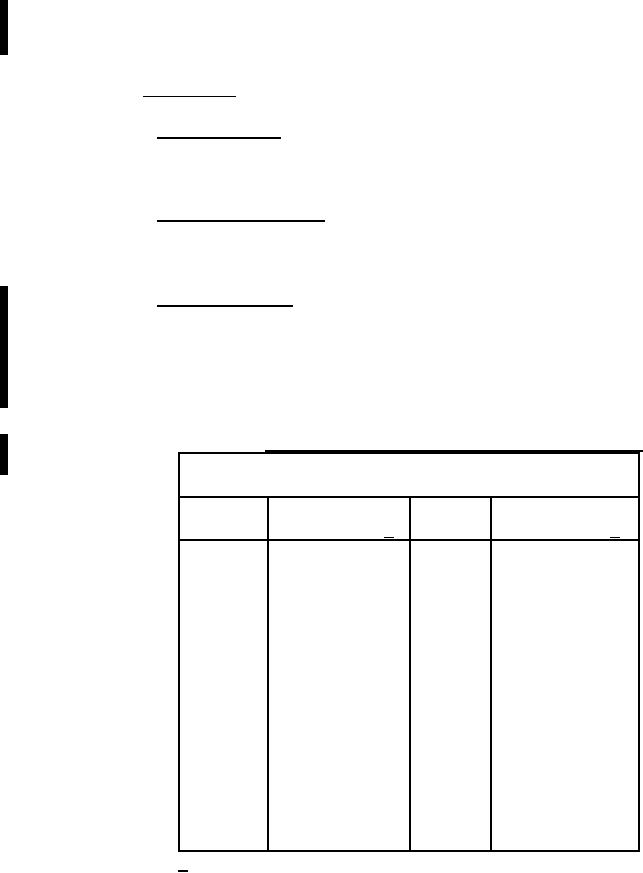

TABLE III. Ballistic Requirements for Class A and B Laminates.

Minimum Required Ballistic Limits CAL 0.30 (44 Grains)

Fragment Simulating Projectile (FSP) at 0° Obliquity

Aramid

V50 protection

Aramid

V50 protection

(plies)

ballistic limit 1/

(plies)

ballistic limit 1/

17

1581

31

2336

18

1626

32

2401

19

1672

33

2468

20

1720

34

2537

21

1769

35

2607

22

1819

36

2679

23

1871

37

2754

24

1924

38

2830

25

1978

39

2908

26

2034

40

2988

27

2091

41

3071

28

2150

42

3155

29

2210

43

3242

30

2272

44

3331

31

2336

45

3423

1/ Average of two ballistic limits, each made on a separate specimen.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business