MIL-DTL-25421C

and 4.4.2.2 respectively, and at the inspection levels and acceptable quality levels

(AQLs) specified therein. The unit of product for determining lot size for these

examinations shall be one plastic sheet or part, as applicable, and the sample unit

shall also be one sheet or part.

4.4.2.1 Examination of sheets or parts for visual defects. This examination

shall be in accordance with Table IV. The inspection level shall be Level I and the

AQL shall be 1.5 defects per 100 units.

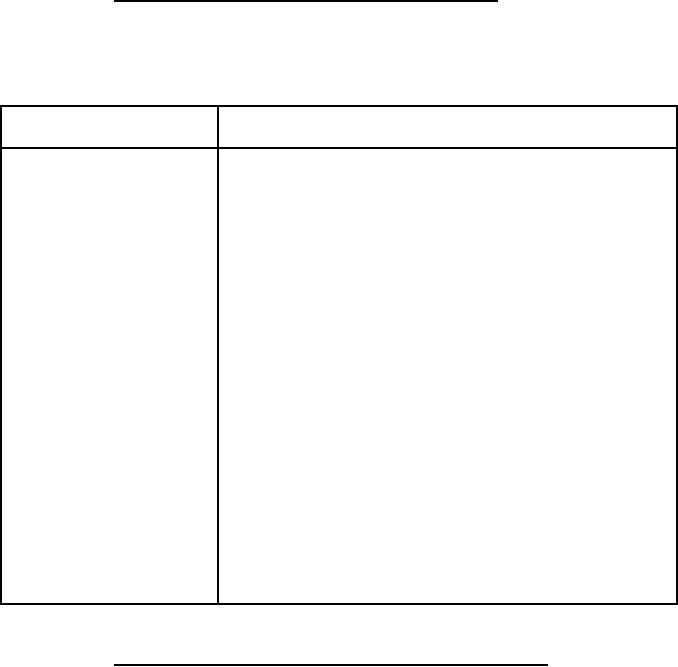

TABLE IV. Examination of Sheets or Parts for Visual Defects

Characteristic

Defect

Shape

Not shape specified.

Appearance

Not uniform in translucence or color. Finish not as

specified, not uniform.

Make-up

Not laminated as specified. Laminations gap.

Overlaps less than ½ inch. Made with resin overlay or

thick resin surface.

Foreign Material

Embedded foreign material, surface dirt, parting

material, or other contaminants.

Workmanship

Cracks, scratches holes, blisters, wrinkles, tacky

surface, resin-starved or porous areas, resin pockets,

chipped or broken parts. Rough surfaces, rough

edges. Sheets not flat when required (curvature

exceeds 1/8 inch per foot of length or width). Reverse

curvature, warped or distorted. Sheets delaminated,

unbonded, or containing air pockets. Patches, except

when specifically permitted as allowable defect.

4.4.2.2 Examination of sheets or parts for dimensional defects. The sample

units shall be examined in accordance with Table V. The inspection level shall be

S-3, and the AQL shall be 2.5 defects for 100 units.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business