MIL-DTL-25421C

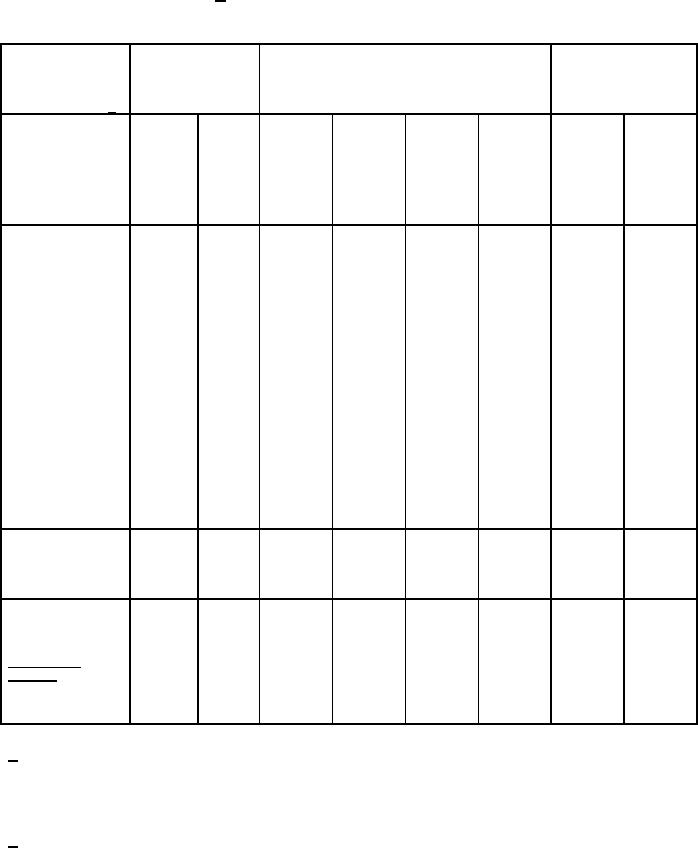

TABLE II. Longitudinal 1/ Mechanical Properties of Epoxy Laminates at Elevated

Temperatures

Glass Fiber

Base

Types I and II

TYPE II

TYPE II

At 70°C

At 260°C

At 260°C

after ½ hour at

after ½ hour at 260° C

after 192 hours at

Cloth number 2/

70°C

260° C

Flexural

Flexural

Flexural

Flexural modulus of

Compres-

Flexural

modulus of

Flexural

modulus of

Strength elasticity

Tensile

sive

Strength

elasticity

Strength

elasticity

(Ultimate) (Initial)

Strength

Strength

(Ultimate)

(Initial)

(Ultimate)

(Initial)

(Thousands (Millions of (Thousands (Thousands (Thousands (Millions of

(Thousands (Millions of

of psi)

psi)

of psi)

of psi)

of psi)

psi)

of psi)

psi)

(Minimum (Minimum (Minimum

(Minimum

(Minimum

(Minimum

(Minimum

(Minimum

(Parallel

Laminated) Average) Average)

Average)

Average)

Average)

Average)

Average)

Average)

(I)

112

65.0

3.2

20.0

10.0

22.0

2.0

18.0

1.8

(IA)

112-150

65.0

3.2

20.0

10.0

22.0

2.0

18.0

1.8

(II)

116

58.0

3.2

20.0

8.0

20.0

2.0

15.0

1.8

(IIA)

116-150

58.0

3.2

20.0

8.0

20.0

2.0

15.0

1.8

(III)

120

65.0

3.2

20.0

10.0

22.0

2.0

18.0

1.8

(IV)

128

58.0

3.2

20.0

8.0

20.0

2.0

15.0

1.8

(IVA)

128-150

58.0

3.2

20.0

8.0

20.0

2.0

15.0

1.8

(IVB)

128-750

58.0

3.2

20.0

8.0

20.0

2.0

15.0

1.8

(V)

143

105.0

5.0

42.0

16.0

40.0

3.3

29.0

2.8

(VA)

143-150

105.0

5.0

42.0

16.0

40.0

3.3

29.0

2.8

(VI)

162

45.0

2.8

20.0

6.0

15.0

2.0

11.0

1.4

(VII)

164

45.0

2.8

20.0

6.0

15.0

2.0

11.0

1.4

(VIIA)

164-150

45.0

2.8

20.0

6.0

15.0

2.0

11.0

1.4

(VIII)

181

65.0

3.2

45.0

10.0

25.0

2.3

20.0

1.9

(VIIIA)

181-150

65.0

3.2

45.0

10.0

25.0

2.3

20.0

1.9

(VIIIB)

181-750

65.0

3.2

45.0

10.0

25.0

2.3

20.0

1.9

(IX)

182

65.0

3.2

21.0

10.0

22.0

2.0

18.0

1.8

(IXA)

182-150

65.0

3.2

21.0

10.0

22.0

2.0

18.0

1.8

(X)

183

58.0

3.2

21.0

8.0

20.0

2.0

15.0

1.8

(XI)

184

58.0

3.2

21.0

8.0

20.0

2.0

15.0

1.8

(XIA)

184-150

58.0

3.2

21.0

8.0

20.0

2.0

15.0

1.8

Mat,

short fibers

32.0

1.6

12.0

8.0

11.0

1.0

8.5

0.85

(Random

laminated)

Mat, nonwoven

continuous

filament

Laminated as

specified

Crossplied

80.0

3.0

28.0

11.0

31.0

2.0

25.5

1.8

Isotropic

60.0

2.2

17.0

9.0

20.0

1.5

16.0

1.4

Unidirectional

100.0

4.5

42.5

15.0

39.0

3.0

32.0

2.6

1/

Except that volume for random laminated and isotropic laminated materials are for random

oriented specimens and values for crossplied laminates are for specimens cut in the stronger

principal direction. By "longitudinal" is meant the warp directions of the parallel laminated cloth

base or filament direction of the unidirectional mat base.

2/

Arabic numerals show the base cloth identification numbers under this specification.

Parenthetical Roman numerals show, for information only, the cloth type designations under

SAE AMS-C-9084.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business