MIL-DTL-25421C

TABLE V. Examination of Sheets or Parts for Dimensional Defects

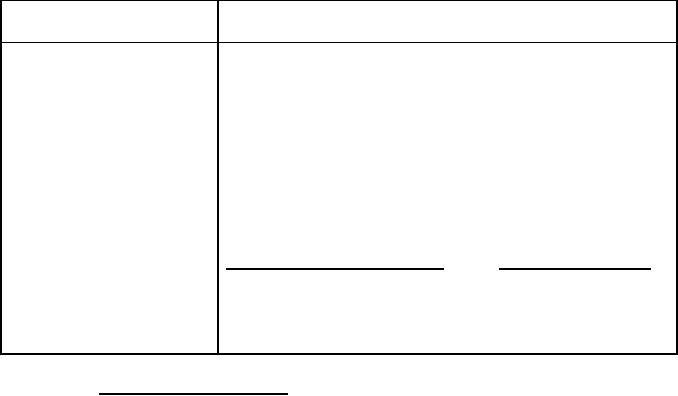

Characteristic

Defect

Length or Width

Varies by more than 1/8 inch or by more than the

tolerances indicated in drawings or requirements, as

applicable.

Thickness

Varies by more than the tolerances indicated in

drawings, specifications, or other requirements. Unless

otherwise specified, the following thickness-tolerance

relationships shall apply:

Specified thickness (inches)

Tolerance (percent)

0.25 or less

± 10

Over 0.25 through 0.50

±7

Over 0.50

±5

4.4.3 Tests of sheets or parts. The sheets or parts shall be subjected to

physical, mechanical, and electrical tests in accordance with Table VI. The unit of

product for determining lot size for these tests shall be one sheet or part. The

sample unit shall be a sufficient area of flat laminate, 0.125 ± 0.010 inch in thickness,

to perform all the applicable tests for Class 1 or Class 2 laminated material, or all the

physical and mechanical tests for Class 3 laminated material. For Class 3 only, the

sample unit shall also include additional flat laminate of sufficient area and suitable

thickness to perform the required electrical tests at 8,500 to 10,000 megacycles.

Unless otherwise specified (6.2), the additional laminate for the Class 3 electrical

tests shall be at least 0.75 inch thick. When required, all sample units shall be cut

into specimens of the number and description specified for the tests of Table VI,

machined to size and suitable for testing. The inspection level for the tests of Table

VI shall be S-1 and the AQL shall be 6.5 defects per 100 units, except that the

minimum sample size shall be three units with an acceptance number of zero for a

sample of that size.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business