MIL-DTL-25421C

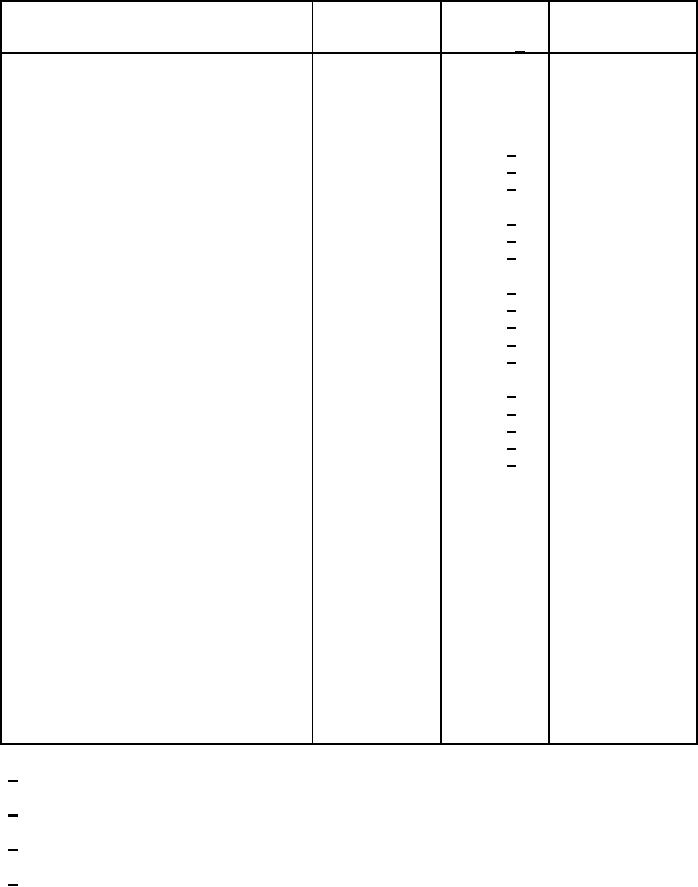

TABLE VI. Laminate Test of Sheets or Parts

Number of

determinations per

Property

Requirement

Method 1/

sample unit

Specific gravity

3.5.1

5011 or 5012

1

Resin content

3.5.1

7061

3

Barcol hardness

3.5.1

4.7.1

10

Tensile strength:

Standard conditions

Table I

1011 2/

5

Wet conditions

Table I

1011 2/

5

260°C, ½ hour (Type II only)

Table II

1011 2/

5

Compressive strength:

Standard conditions

Table I

1021 3/

5

Wet conditions

Table I

1021 3/

5

260°C, ½ hour (Type II only)

Table II

1021 3/

5

Flexural strength, Ultimate

Standard conditions

Table I

1031 4/

5

Wet conditions

Table I

1031 4/

5

70° C, ½ hour

Table II

1031 4/

5

260°C, ½ hour (Type II only)

Table II

1031 4/

5

260°C, 192 hours (Type II only)

Table II

1031 4/

5

Flexural modulus of elasticity, initial

Standard conditions

Table I

1031 4/

5

Wet conditions

Table I

1031 4/

5

70° C, ½ hour

Table II

1031 4/

5

260°C, ½ hour (Type II only)

Table II

1031 4/

5

260°C, 192 hours (Type II only)

Table II

1031 4/

5

Dielectric constant at 1 megacycle

(Class 2 Only):

Standard conditions

Table III

4021

4

After immersion

Table III

4021

4

Loss tangent at 1 megacycle (Class 2 only):

Standard conditions

Table III

4021

4

After immersion

Table III

4021

4

Dielectric constant at 8,500 to 10,000

megacycles (Class 3 only):

Standard conditions

Table III

4.7.2

4

After immersion

Table III

4.7.2

4

Loss tangent at 8,500 to 10,000 megacycles

(Class 3 only):

Standard conditions

Table III

4.7.2

4

After immersion

Table III

4.7.2

4

1/

Method references other than paragraph numbers refer to methods of ASTM D2240.

2/

Tensile specimens to be Type II of Method 1011.

3/

Compression specimens to be tested edgewise by thin-sheet procedure.

4/

Flexural specimens to be tested flatwise.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business