MIL-DTL-25421C

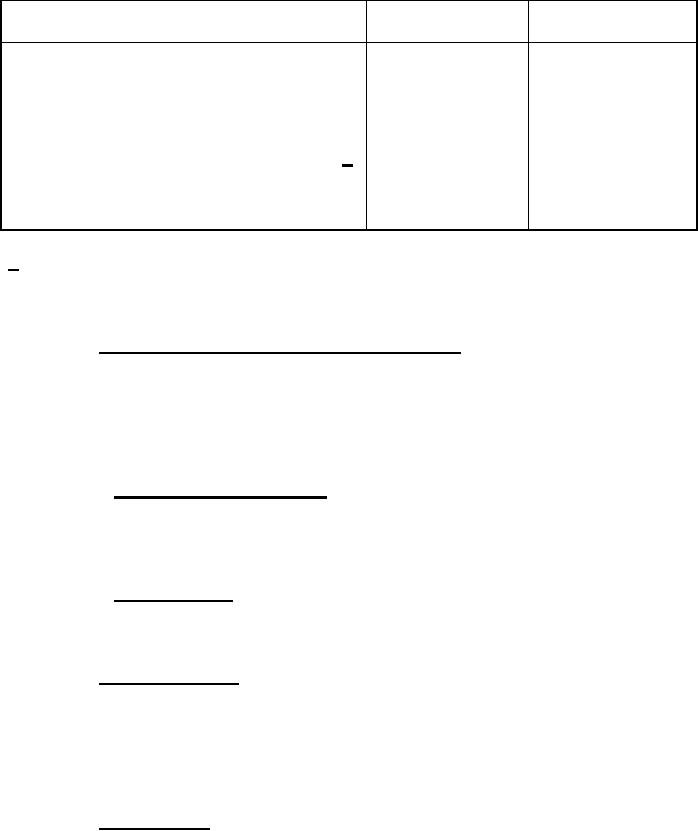

TABLE III. Electrical Requirements for Classes 2 and 3 Laminated Materials

(see also 6.3)

Standard

Immersion

Characteristic

Conditions

Conditions

Class 2 (At 1 megacycle)

Dielectric contstant (max)

4.4

4.6

Loss tangent (max)

0.045

0.055

Class 3 (At 8,500 to 10,000 megacycles) 1/

Dielectric contstant (max)

4.6

4.6

Loss tangent (max)

0.020

0.025

1/

"X-band" frequency range. The recommended test frequency for this band is

9,375 megacycles per second (6.3).

3.4.4 Shape, dimensions, and make-up of laminate. The shape, thickness, and

surface dimensions of the laminate, the number of component plies of glass cloth or

mat in the laminate, the position and direction of the plies, and other specific details

of the laminate parts or end items shall be as specified herein and in the drawings or

specifications for the part or end item (3.1). Dimensional tolerances shall be as

shown in Table V.

3.4.4.1 Gaps or laps in fabric plies. There shall be no gaps between pieces of

glass fabric in any lamination. When laps are necessary, they shall be laid up with a

lap width of at least ½ inch. No two laps shall be superimposed upon each other in

the plastic.

3.4.4.2 Resin overlays. The laminated plastic materials shall not be made with

a gel resin overlay, integrally molded or otherwise, or with any other such thick-resin

surface or surfacing material.

3.4.5 Foreign materials. No metal staples, paper tape, fillers (except in mat

laminates (3.3.3)), or other foreign materials shall remain in the finished plastic

laminate, unless permitted by the applicable drawings or specifications. Parts to

which rain-erosion resistant coatings or other coatings are subsequently to be

applied, shall be cleaned free of surface contamination, such as parting agents,

which might adversely affect the adhesion of the coating.

3.4.6 Workmanship. The plastic material shall be uniform, smooth, and free

from uncured or unbounded areas, gaps, cracks, holes, blisters, resin pockets, areas

lacking resin, tackiness, excess surface resin, incorrect laps, wrinkles, delamination,

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business